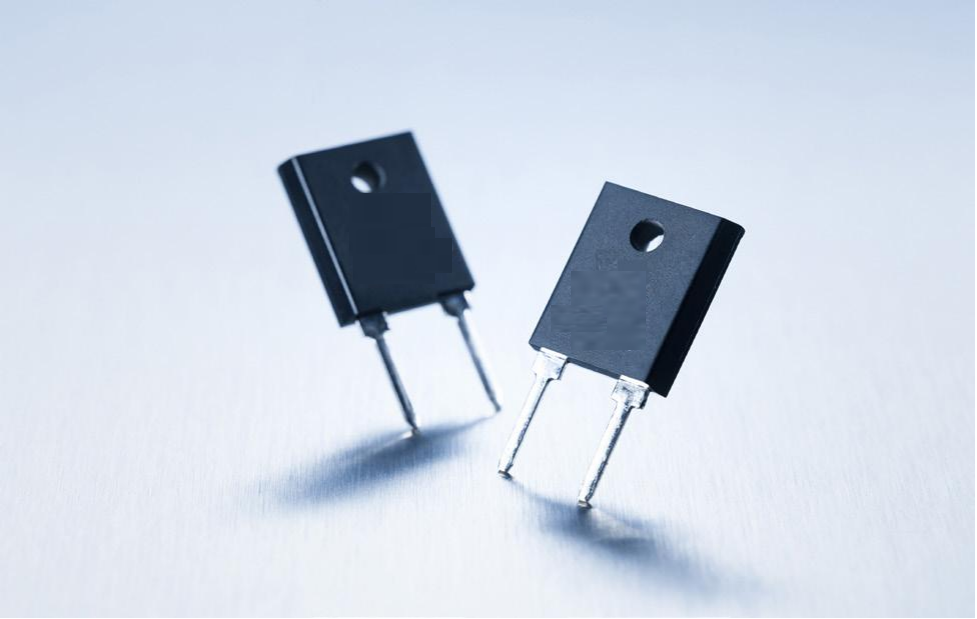

To-247 power resistor of EAK for design engineers to provide a stable transistor-type package of high-power resistor devices, power is 100W-150W

These resistors are designed for applications that require precision and stability. The resistor is designed with an alumina ceramic layer that separates the resistor element from the mounting plate.

Eak molded TO-247 thick film power resistor

This structure provides very low thermal resistance while ensuring high insulation resistance between the terminal and the metal backplane. As a result, these resistors have very low inductance, making them suitable for high-frequency and high-speed pulse applications.

The resistance ranges from 0.1Ωto 1 MΩ,Working temperature range:-55°C to +175°C.

EAK will also produce equipment beyond these specifications to meet customer requirements. EAK power resistors comply with ROHS standards, using lead-free termination.

Features:

■100 W operating power

■TO-247 package configuration

■Single-screw mounting simplifies attachment to heat sink

■Non-Inductive design

■ROHS compliant

■Materials in accordance with UL 94 V-0

M3 screw mount to radiator. The molded enclosure provides protection and is easy to install. Non-inductive design, electrical isolation housing.

Application:

■Terminal resistance in the RF power amplifier

■Low energy pulse load, grid resistor in power supply

■UPS, buffers, voltage regulators, load and discharge resistors in CRT monitors

Resistance ranges:0.05 Ω ≤ 1 MΩ (other values on special request)

Resistance Tolerance: ±1 0% to ± 1 %

Temperature Coefficient:≥ 10 Ω: ±50 ppm/°C referenced to 25 °C, ΔR taken at +105°C

(other TCR on special request for limited ohmic values)

Power rating:100 W at 25°C bottom case temperature derated to 0 W at 175°C

Maximum operating voltage:350 V , max. 500 V on special request

Dielectric strength voltage: 1,800 V AC

Insulation resistance:> 10 GΩ at 1,000 V DC

Dieletric strength: MIL-STD-202, method 301 (1,800 V AC, 60 sec.) ΔR < ±(0.15 % + 0.0005 Ω)

Load life:MIL-R-39009D 4.8.13, 2,000 hours at rated power, ΔR < ±(1.0 % + 0.0005 Ω)

Moisture resistance:-10°C to +65°C, RH > 90 % cycle 240 h, ΔR < ±(0.50 % + 0.0005 Ω)

Thermalshock:MIL-STD-202, method 107, Cond. F, ΔR = (0.50 % + 0.0005Ω) max

Working temperature range:-55°C to +175°C

Terminalstrength:MIL-STD-202, method 211, Cond. A (Pull Test) 2.4 N, ΔR = (0.5 % + 0.0005Ω)

Vibration, high frequency:MIL-STD-202, method 204, Cond. D, ΔR = (0.4 % + 0.0005Ω)

Lead material:tinned copper

Torque:0.7 Nm to 0.9 Nm M4 using a M3 screw and a compression wahser mounting technique

Heat resistance to cooling plate:Rth < 1.5 K/W

Weight:~4 g

Application Guide for Radiator Mounted Power film resistors

Know the temperature and power rating:

Figure 1-understand temperature and power rating

Assembly of heat-conducting materials:

1,There is a gap due to a change in the mating surface between the resistor package and the radiator. These voids will greatly reduce the performance of the TO-type equipment. Therefore, the use of thermal interface materials to fill these air gaps is very important. Several materials can be used to reduce the thermal resistance between a resistor and a radiator surface.

2,Heat-conducting silicone grease is a combination of heat-conducting particles and fluids that combine to form a consistency similar to that of a grease. This liquid is usually silicone oil, but now there is a very good“Non-silicon” heat conductive silicone grease. Thermally conductive silicone resins have been used for many years and usually have the lowest thermal resistance of all available thermally conductive materials

3,Heat-conducting gaskets are substitutes for heat-conducting silicone and are available from many manufacturers. These pads have a sheet or pre-cut shape and are designed for a variety of standard packages such as TO-220 and To-247. The heat conduction gasket is a spongy material, needs the uniform pressure and the firm performance to be able to work normally.

Selection of hardware components:

Proper hardware is an extremely important consideration in good cooling design. The hardware must maintain a firm and uniform pressure on the equipment through thermal cycling without distorting the radiator or equipment.

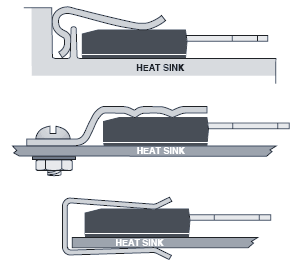

Many designers prefer TO connect the DeMint TO power resistor TO the radiator using a spring clip instead of a screw assembly. These spring clips are available from a number of manufacturers that supply many standard springs and radiators designed specifically for clip mounting in TO-220 and To-247 packages. The spring clamp has many advantages that are easy to assemble, but its greatest advantage is that it consistently exerts the best force in the center of the power resistor (see Figure 2)

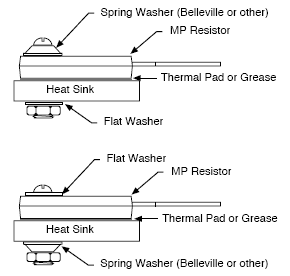

Fig. 3-screw and washer mounting technique

Screw Mounting-belleville or tapered washers used with screws are an effective way to connect to the radiator. Belleville washers are tapered spring washers designed to maintain constant pressure over a wide deflection range. Gaskets can withstand long-term temperature cycles without pressure changes. Figure 3 shows some of the typical hardware configurations for mounting the TO package screw TO the radiator. Plain washers, star washers, and most split lock washers should not be used in place of Belleville washers as they do not provide a constant mounting pressure and may damage the resistor.

Assembly notes:

1,Avoid using the TO series power resistors in SMT assemblies.

2,Plastic mounting hardware that softens or creep at high operating temperatures must be avoided

3,Do not let the screw head touch the resistor. Use plain washers or tapered washers to evenly distribute the force

4,Avoid sheet metal screws, which tend to roll up the edges of the holes and create destructive burrs in the radiator

5,Rivets are not recommended. Using rivets is difficult to maintain consistent pressure and can easily damage plastic packaging

6,Don't overdo the torque. If the screw is too tight, the package may break at the farthest end of the screw (the lead end) or have a tendency to bend upward. Pneumatic tools are not recommended.

Post time: Mar-14-2024